EQ Electric Hoist - 3 Phase

A True Powerhouse in a Small Body

EQ Electric Hoist - 3 Phase

A True Powerhouse in a Small Body

| Harrington's EQ dual speed VFD 3-phase electric chain hoists are designed for medium to heavy-duty industrial and workstation applications. These hoists include a unique no-load high speed function that automatically increase hoist speed up to 130% when the load is less than 30% of working load limit. |

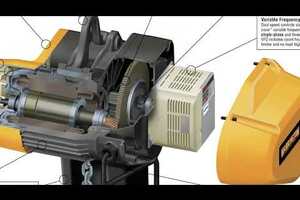

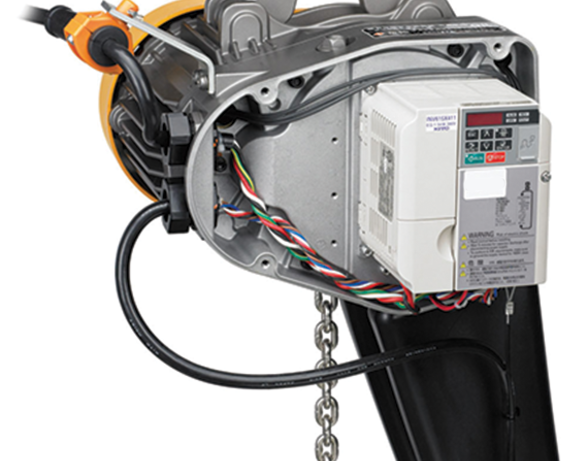

Variable Frequency Drive (VFD)

All models come with a standard “under-the-cover” variable frequency drive – regardless of voltage. This device works by varying the power to the motor, which allows you to adjust both the high and low speeds. It also provides a soft-start/soft-stop operation to reduce shock loads, swing, and bounce – resulting in more precise load control and longevity of the hoist.

COMPACT ALUMINUM BODY

Die-cast body is lightweight and offers low headroom – one of the best in the industry. Paint is electrostatically applied.

Unique Chain Guide

Provides quiet and smooth guiding of chain. Heavy cast iron construction for improved wear versus stamped steel design offered by many manufacturers.

Self-Adjusting Maintenance-Free Brake

Equipped with our pull-rotor motor brake, the EQ has no brake coil to fail or discs to replace, making it virtually maintenance free.

NO-LOAD HIGH SPEED

When working with less than 30% of the full rated capacity, the EQ can operate 1.3 times faster, optimizing your work efficiency and production time.

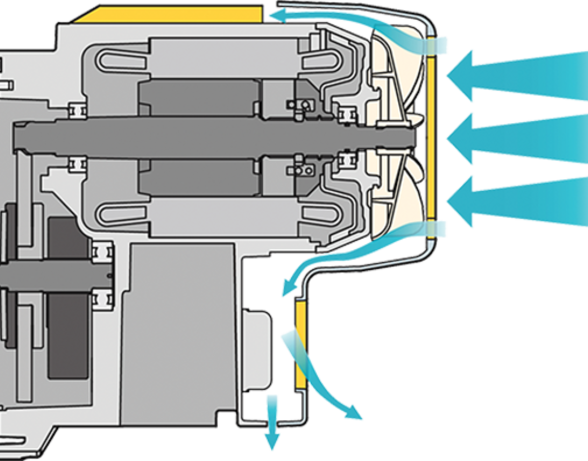

Extreme Duty, Three-Phase, Fan-Cooled Motor

Rated for an ASME H4 Classification, the motor has a 30/10 minute duty rating in a three phase, dual speed offering. The external motor fan functions to quickly eliminate resistor, motor, and brake heat.

CAPACITY

- 1/8 to 1 Ton

VOLTAGE

- (208-230)-3-50/60

- (380-460)-3-50/60 - Note: Supply voltage is (380-440)-3-50/60 or (415-460)-3-50/60 when coupled with MRQ trolley

COMPLIANCE

- UL 508, 508A, 1004

- CSA C22.2 NO.33,14-13, 66

- ANSI/NFPA 70, “National Electrical Code”

- ANSI/ASME B30.16, “Safety Standard—Overhead Hoists (Underhung)”

- ANSI/ASME HST—1M, “Performance Standard for Electric Chain Hoists”

CLASSIFICATION

- ASME H4

- ISO 1/8-1/2T M6; 1T M5

- FEM 1/8-1/2T 3m; 1T 2m

BODY

- Gaskets throughout the hoist provide for a IP55 rating

- Die-cast aluminum

- Completely sealed body for for both indoor and outdoor applications, including harsh environments.

- Low headroom

- Paint is electrostatically applied

- Plastic chain container standard

GEARS

- Precision machined helical gears immersed in oil bath lubrication for quiet, smooth and cool operation

LOAD CHAIN

- Ultra-strong high-performance and corrosion resistant nickel-plated

- Grade 80 DIN chain

OPERATION

- Pendant control

- Under-the-cover VFD standard

HOOKS

- Forged carbon steel

- Open gradually without fracturing under excessive loads

- Bottom hook swivels 360 degrees

- Top and bottom hooks have heavy-duty hook latch

PUSH BUTTON PENDANT

- Rated IP65

- Standard control voltage is 24VDC

- Strain relief wire is molded to pendant cord for added support and dependability

- 2-button (momentary contacts) with emergency On/Off (maintained contacts)

- E-stop is standard on all pendants

BRAKE

- Extremely durable and reliable pull-rotor motor brake

- Contains no brake coil to fail like conventional disc brakes

MOTOR

- Totally enclosed fan-cooled (TEFC)

- External motor fan quickly eliminates resistor, motor and brake heat

- 30/10-minute duty rating, H4 classification, Class B insulation, cooling fins and external thermal motor protection

OPERATING CONDITIONS

- Recommended for -4° to +104° F and humidity of 85% or less

OPTIONS

- Longer lift or pendant lengths

- Suspension bar for low headroom or enclosed track trolley applications

- Longer lift canvas chain containers