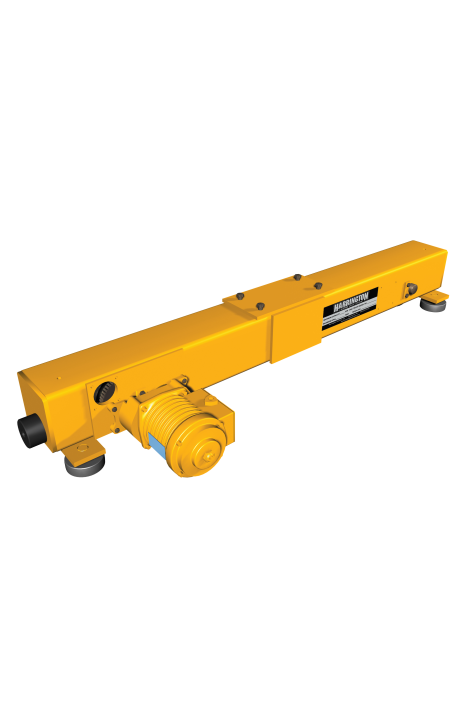

Single Girder Top Running Motorized End Trucks

Quality to Count On

Single Girder Top Running Motorized End Trucks

Quality to Count On

For heavy-duty class “C” single girder crane applications, nothing tops Harrington top running motorized end trucks. Superior strength, rigidity and compactness comes from frame fabrication of ASTM A500 structural tube.

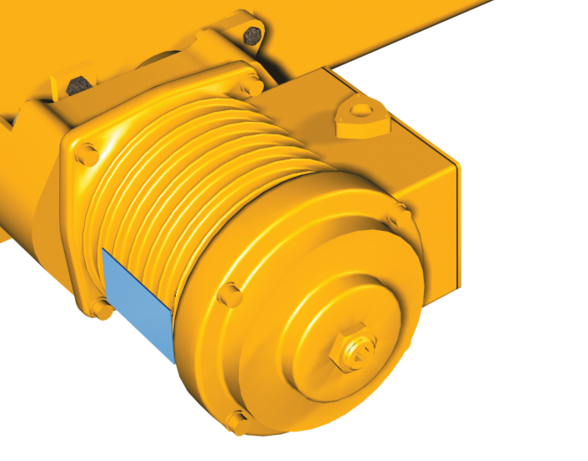

Heavy-Duty Drives

Heavy-duty drives are designed for crane service with 30 minute rating and feature cooling fins for efficient heat dissipation.

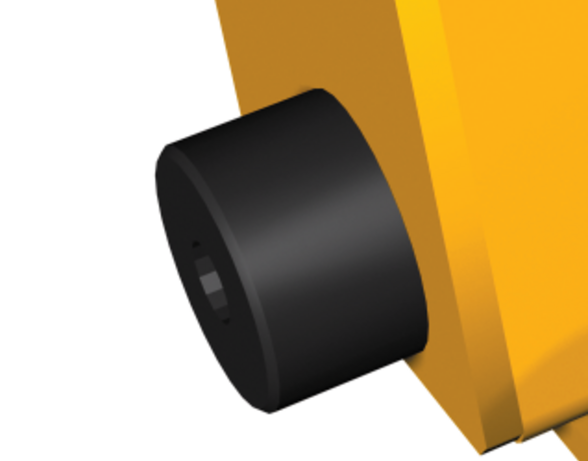

Rubber Bumpers

Standard rubber bumpers are included for protection from collision.

Minimize Assembly Labor

Fully machined frames—girder connection, bracing and collector mounting bracket holes are drilled and tapped for easy installation.

Heavy Duty Side Guide Rollers

Reduced wheel friction due to heavy-duty side guide rollers results in smooth crane travel. Guide rollers are 3 1/2" O.D. with fixed steel axels.

CAPACITY/SPAN

- 1 - 10 Ton/Up to 60' Span

SERVICE CLASS

- Class C

COMPLIANCE

- Crane Manufacturers Association of America (CMAA)

- National Electric Code (NEC) and the American National Standards Institute (ANSI/ASME)

END TRUCKS INCLUDE

- Two fully painted trucks

- Two sealed, totally enclosed, non-ventilated (TENV) motors with adjustable D.C. brakes

- Two helical gear reducers

- Rubber bumpers

- Bridge beam fastener set

- Bridge fabrication prints

BODY

- Frame fabrication from ASTM A500 structural tube for superior strength, rigidity and compactness

- Minimize assembly labor with fully machined frames

- Girder connection, bracing and collector mounting bracket holes are drilled and tapped for easy installation

DRIVES AND BRAKES

- Sealed TENV drives with quiet, smooth–operating helical gear reducers

- Drives are designed for crane service, with 30 minute rating and feature cooling fins for efficient heat dissipation

- Drives are connectable for 230/460V-3-60 (including dual speed models)

- Drives and brakes are compatible with Electronic Acceleration Control (EAC) and Variable Frequency Drive (VFD)

- Externally adjustable D.C. brakes allow controlled deceleration—adjustable up to 50% of rated motor torque

FEATURES

- Reduced wheel friction with heavy-duty side guide rollers results in smooth crane travel

- Guide rollers are 3 1/2" O.D. (5" on 10 T) with fixed steel axles

- Suitable for use on ASCE crane rail or square bar—wheels are machined steel with flat tread and each has 2 deep groove ball bearings

- Gear reducer is designed for easy field conversion between L and S speeds

- Rail sweeps

- Drop stops

OPTIONS

- Longer or shorter end truck lengths are available

- Other voltages