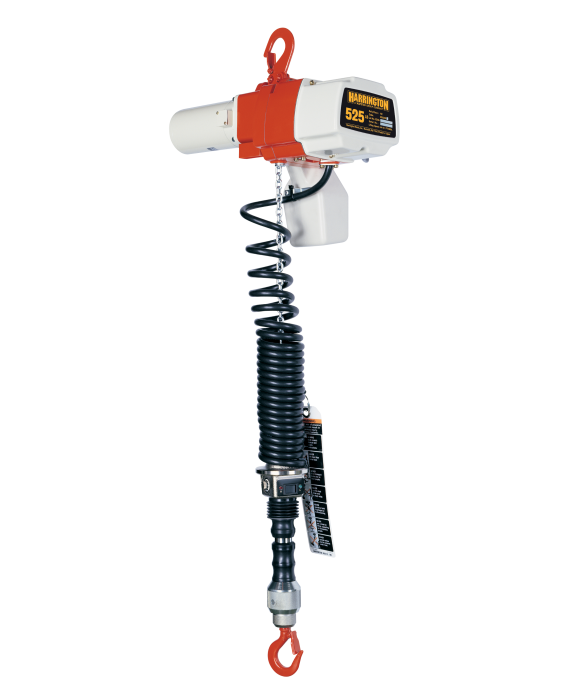

SNER Electric Hoist - 1 Phase

Household Voltage - Industrial Power

SNER Electric Hoist - 1 Phase

Household Voltage - Industrial Power

Need a single speed, single phase hoist with the duty cycle of a three-phase hoist? Look no further than the SNER. Designed to exceed H4 industrial use ratings, the SNER is equipped with a TEFC motor and a maintenance-free, self-adjusting, pull-rotor brake. That means you’ll get a single phase hoist that’s able to handle the long lifts and long shifts of any industrial job.

Extreme-Duty, Single-Phase Fan-Cooled Motor

The SNER electric hoist is equipped with a 60-minute H4-rated motor which is unmatched in a single-phase offering. Built for extremes, the SNER delivers proven performance in the most demanding applications.

Self-Adjusting Maintenance-Free Brake

With no brake coil to fail or discs to replace, the electromagnetic pull rotor brake on the SNER is self-adjusting and virtually maintenance-free.

Long-Life

Friction Clutch

The friction clutch is designed to last so you can focus on the job at hand. Lift longer with protection from overloading and overwinding which can damage the hoist.

Heavy Cast-Iron Chain Guide

The heavy cast-iron chain guide provides quiet and smooth chain movement. Easily removed without disassembly of the hoist, it allows for easy maintenance in those demanding heavy-duty applications.

Oil Bath-Lubricated, Heat-Treated Gearing

Harrington’s own heat-treating process increases the overall hardness and strength of internal parts which run smoothly when immersed in an oil bath. This extends service life by reducing friction, vibration, and heat.

CAPACITY

- 1/4 - 3 Ton

VOLTAGE

- 115/230-1-60

- Reconnectible voltage

STANDARDS

- ANSI/NFPA 70, “National Electrical Code”

- ANSI/ASME B30.16, “Safety Standard—Overhead Hoists (Underhung)”

- ANSI/ASME HST—1M, “Performance Standard for Electric Chain Hoists”

BODY

- Compact die-cast aluminum

- Completely sealed body suitable for indoor, outdoor and harsh environments

- Easy maintenance hinged control panel for quick access

GEARS

- Heat treated helical and spur gears

- Submersed in an oil bath for quiet, smooth, cool operation

LOAD CHAIN

- Ultra-strong high-performance and corrosion resistant nickel-plated

- Grade 80 chain

- Made with unique technology to greatly increase resistance to fatigue and wear

CHAIN GUIDE

- Long-lasting, heavy cast iron construction

- Provides quiet and smooth guiding of the chain

- Easily replaced without disassembling the hoist

HOOKS

- Forged carbon steel opens gradually without fracturing under excessive loads

- Bottom hook swivels 360 degrees

- Top and bottom hooks have heavy-duty hook latch

CONTROLS

- Pendant control

- 110V

PUSH BUTTON STATION

- Impact-resistant plastic with molded strain relief to avoid damage from pulling on the push button cord

- Rated IP65

BRAKE

- Durable and reliable pull-rotor motor brake

- Has no brake coil to fail

MOTOR

- Totally enclosed fan cooled (TEFC)

- 60 minute, H4 rated for demanding applications

PROTECTION

- Long-life friction clutch protects hoist from damage

- Upper limit switch prevents overwinding/overlifting

OPTIONS

- Canvas, plastic or steel chain containers

- Longer lift or pendant lengths

- Thermal overload protection