MR Motorized Trolleys

Heavy-Duty Moving Power

MR Motorized Trolleys

Heavy-Duty Moving Power

Harrington's MR three-phase motorized trolleys easily couple with our (N)ER electric chain hoists and provide excellent traversing motion and control. MR electric trolleys are built for the most demanding applications so you can count on them day in and day out.

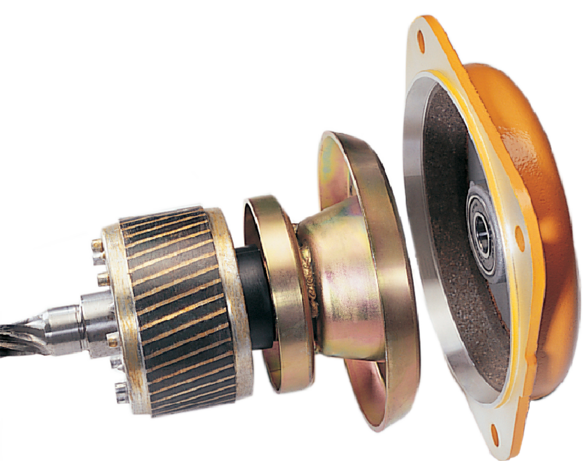

Pull-Rotor Motor Brake

Extremely durable and reliable, this advanced design furnishes precision load control, deceleration and long life.

Rubber Bumpers

This feature is standard on all motorized trolleys to provide protection from collisions. Complies with ASME standards.

Side Guide Roller

Four ball bearing supported rollers enhance smooth trolley motion and reduce wear of the wheels and beam.

CAPACITY

- 1/8 - 20 Ton

VOLTAGE

- 208-230/460-3-60

OPERATION

- Pendant control

OPERATING CONDITIONS

- Temperature range +14° to 140°F

- Humidity 85% or less

RATING

- IP55

COMPLIANCE

- OSHA Section 1910.179 of Title 29, “Occupational Safety and Health Regulations—Overhead and Gantry Cranes”

- ANSI/ASME B30.11, “Safety Standard—Monorails and Underhung Cranes”

- ANSI/ASME B30.17, “Safety Standard—Overhead and Gantry Cranes (Top Running Bridge, Single Girder, Underhung Hoist)”

BRAKE

- Extremely durable and reliable pull-rotor motor brake furnishes precision load control, deceleration and long life

MOTOR

- Designed for top performance with high-horsepower, 30-minute duty rating, cooling fins and standard thermal motor protection

- Totally enclosed, non-ventilated (TENV)

BODY

- Sealed for both indoor and outdoor applications, including harsh environments

- Gaskets throughout the trolley provide for an IP55 rating

- Pendant plug-in connections saves valuable time on setup and maintenance

TROLLEY FEATURES

- Standard shafts with spacers for easy adjustments fit wide flange range

- Drop Stops

- Bumpers

- All steel wheels have shielded ball bearings and will fit flat or tapered beam flange

- Cable support arm assembly (tow bar) gives support and guides the power supply festooning

OPTIONS

- Longer pendant lengths

- Extended flange ranges

- Other voltages