Acco WRIGHT® Speedway® Wire Rope Hoists

Designed for H4 Duty

Acco WRIGHT® Speedway® Wire Rope Hoists

Designed for H4 Duty

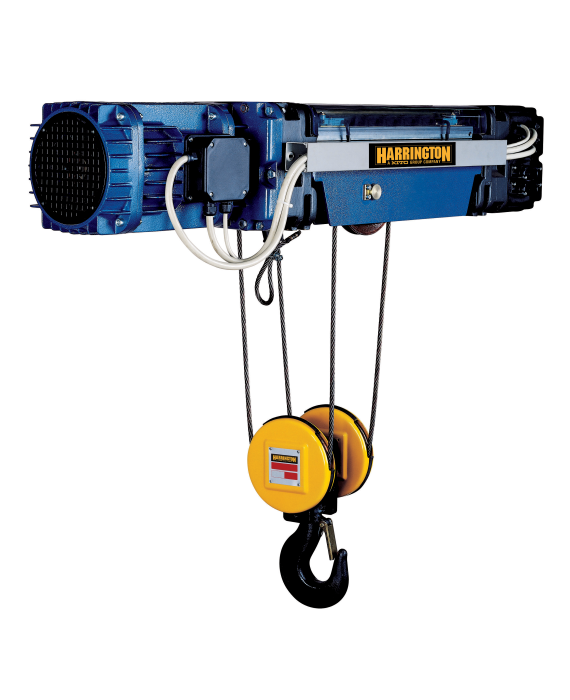

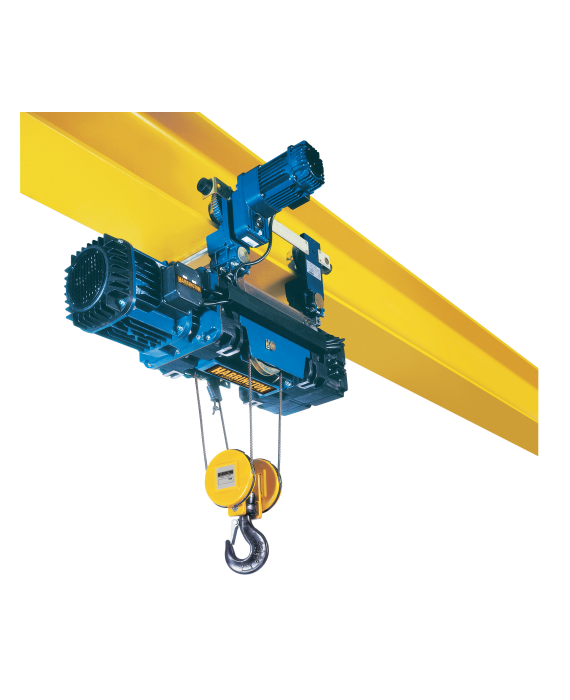

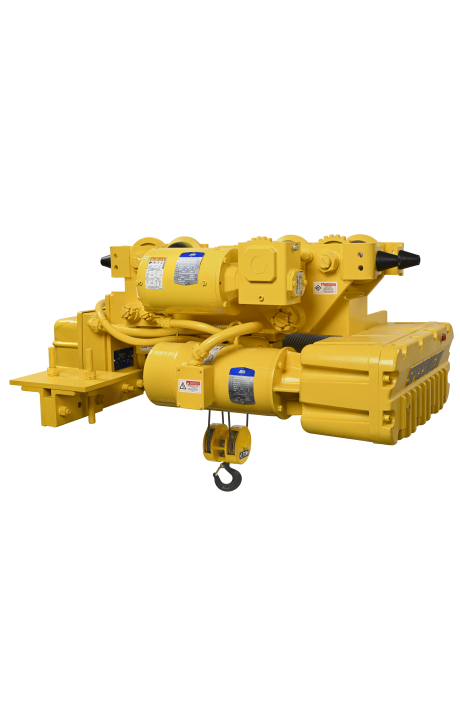

Acco Wright® Speedway® hoists are engineered to exact specifications in Monorail, Close Headroom Cross Mounted, Top Running Trolley or Deck Mounted configurations. Our hoists are designed for operating 30 minutes of each hour with a maximum of 300 starts an hour as defined by Hoist Duty Class H4 of ASME HST-4M.

Mechanical Load Brake

Automatic Weston-Type multiple disc brake can hold a full capacity load independent of the motor brake and assures that the load does not accelerate while being lowered. Adjustment is not required.

MOTOR

The New Century Series utilizes a U.S. manufactured motor, 30-minute duty, Class F insulation. Standard single speed motor is provided for 200V, 30V/460V, or 575V 3 phase, 60 hertz power supplies. Motor thermostats are standard - providing both running and overcurrent protection.

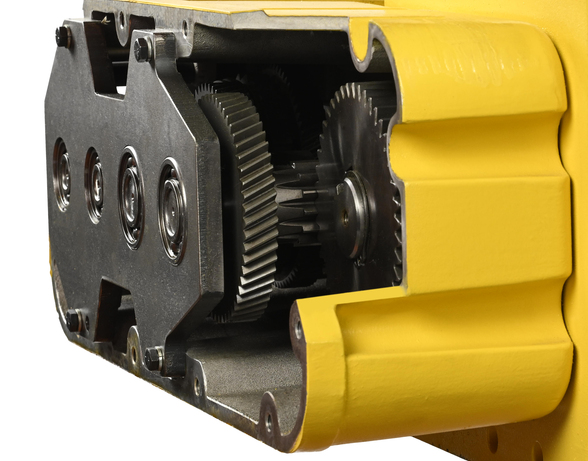

BEARINGS - SPIDER RETAINER

Precision heavy-duty ball bearings support all shafts. Bearings at outboard end of shafts are held in place by a heavy-duty Spider Retainer. This allows removal of Gear Housing Cover for inspection (after draining oil). All internal parts remain in place and can be operated for inspection.

Motor Brake

Proven in millions of hours of in-service operation, the original Wright A-C magnet-actuated disc brake delivers rapid stops with virtually no hook drift. Rated a minimum of 150% of full load motor torque.

CAPACITY

- 1-5 Ton

COMPLIANCE

- ASME B30.16 and ASME HST 4M Standards

WIRE ROPE

- Pre-formed wire rope, of hoisting service construction, has swaged fittings on both ends for ease of replacement if necessary

STANDARD VOLTAGE

- 200V, 230V, 460V, or 575V

MOTOR

- Utilizes a U.S. manufactured motor, 30-minute duty, Class F insulation

- Standard single speed motor is provided for 200V, 230V/460V, or 575V 3 phase, 60 hertz power supplies

- Motor thermostats are standard - providing both running and overcurrent protection

GEARS

- Quiet, helical, and spur gearing.

- All gears are machine cut, case-hardened alloy steel with shock-resistant ductile cores

- Designed to AGMA standards

CONTROLS

- Choose single or two speed

- Magnetic reversing contactors, both mechanically and electrically interlocked

- 115V control circuit

- Meets NEC requirements

- NEMA Type 3R enclosure

- Lightweight, durable, and easily accessible

BRAKE

- Proven in millions of hours of in-service operation

- The Wright A-C magnet-actuated disc brake delivers rapid stops with virtually no hook drift

- Rated a minimum of 150% of full load motor torque

HOOK BLOCK

- Drop forged heat-treated steel hook swivels 360° on a shielded roller thrust bearing

- Equipped with a spring latch

- Work can be performed on the load block without removing wire rope from drum

- Sheaves are machined steel with machine finished grooves, to increase surface contact with hoisting rope

OPTIONS

- Overload cutoff

- Geared limit switch

- Motor fuse holders and fuses

- Variable speed by inverter control

- Bullard hook

- Trolley modifications & speeds

- Operational on patented track

- ACM trolleys and brakes

- Trolley drop down lugs & bumpers

- Tagline tow arm

- Epoxy paints

- Audible or visual hoist overload indicator

- Running time meter

- Class I and Class II Hazardous Location Applications