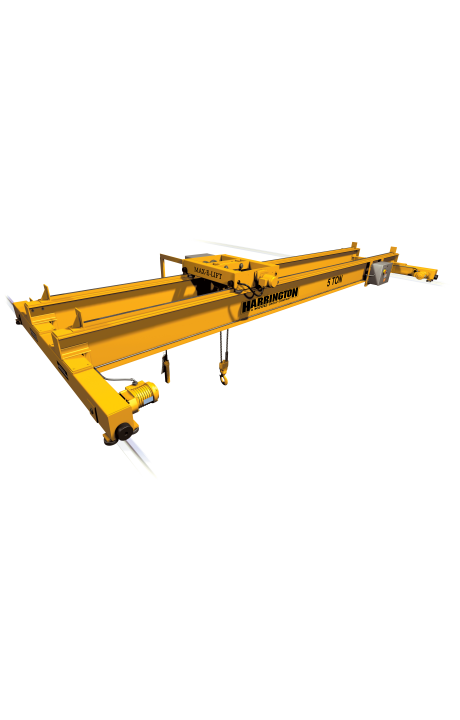

Double Girder Cranes

Minimize Wasted Overhead Space and Maximize Available Lifting Height

Double Girder Cranes

Minimize Wasted Overhead Space and Maximize Available Lifting Height

Our top running and underhung double girder design and low profile trolley hoist saves much of the space "wasted" on conventional single girder designs. So for new installations, our Max-E-Lift system saves valuable overhead room and can reduce building height and construction costs. Adding a Max-E-Lift crane to an existing installation where a new, higher lifting height is required can even minimize total construction costs.

Max-E-Lift Double Girder Systems

These systems allow for maximum headroom and hook height that traditional cranes cannot accommodate.

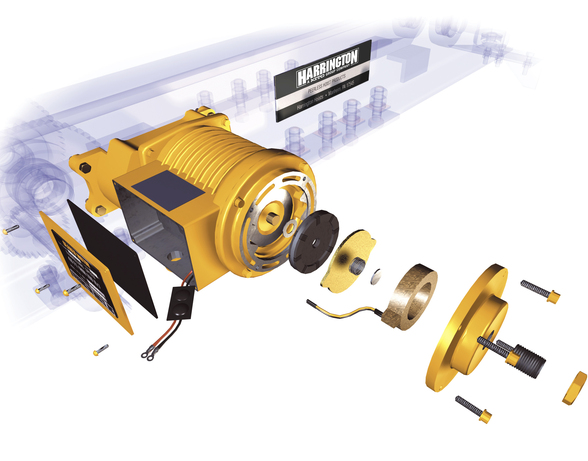

Reliable Motor and Brake

Harrington motorized cranes are dual drive type, employing two totally enclosed non-ventilated drives per crane. Drives use helical and spur gearing and are equipped with adjustable DC brakes.

Hassle-Free Set Up

These systems use bolted construction with minimal welding required and factory installed or plug-in type wiring connections that will make installation quick and easy.

Tested and Verified

Feel confident that you are getting properly designed and manufactured products with our UL/C-UL Listed bridge crane control panels and our CSA and UL Listed crane wires and festooning.

CAPACITY / SPAN

- Top Running 1 - 10 Ton - Up to 60' Span

- Underhung 1 Ton through 5 Ton - Up to 50' Span

SERVICE CLASS

- Class C

COMPLIANCE

- Crane Manufacturers Association of America (CMAA)

- National Electric Code (NEC)

- American National Standards Institute (ANSI/ASME)

STANDARD FEATUERES

- Bolted assembly for quick and easy installation

- Minimal welding required

- Most wiring connections are factory installed or plug-in type

- Rail sweeps

- Drop stops

- Rubber bumpers

CAPABILITIES

- Fully customizable to suit any lifting need

OPTIONS

- Variable frequency control or two speed, radio remotes

- Roving pendants