RNER2 CII/D2 Hazardous Location Electric Hoists

Protection in Haz Loc Environments

RNER2 CII/D2 Hazardous Location Electric Hoists

Protection in Haz Loc Environments

Our RNER2 Series three phase hazardous location electric chain hoists are designed for use in Class II Division 2 locations where fire or explosion hazards may exist due to combustible dust.

Hazardous Location Use - Dust Only

DUST: Class II Division 2

Group F (example: Coal dust) and Group G (example: Grain dust)

WARNING: Always consult a Qualified Person regarding hazardous locations and selection of equipment suitable for your specific application.

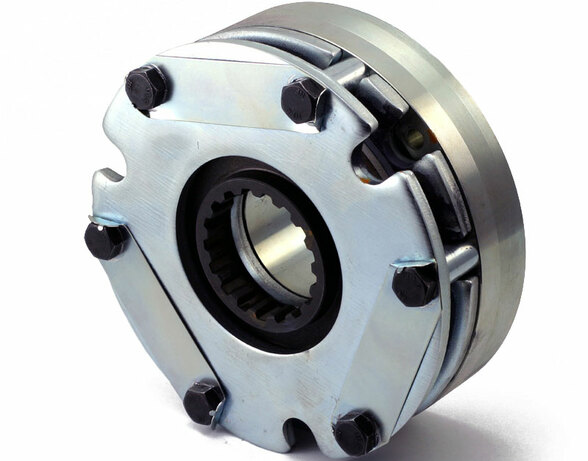

Smart Brake Technology

The RNER2 Guardian Smart Brake has an electrical fail-safe design that uses DC current to control brake activation. The fast activation drastically reduces wear on the brake discs, preserving the correct brake gap. The result is a maintenance-free braking system with a 10-year hoist brake warranty.

UL Listed

RNER2 hoists in standard configurations (including certain options) are certified and listed to applicable UL standards.

State-Of-The-Art Chain Technology

Our RNER2 uses Harrington world-class, super-strength chain. Its shorter and narrower link profile allows for greater surface area contact, giving it better wear resistance and overall tensile strength.

RNER2 Hazardous Location Hoists Video

RNER2 HazLoc Electric Hoists are designed specifically for those industrial locations where fire or explosion hazards may exist. All Harrington HazLoc hoists are certified and listed to applicable UL standards and are equipped with top quality features providing safe, efficient, and trouble-free lifting in the most demanding environments.

HAZARDOUS AREA

- Class II / Division 2

PROTECTED DUST GROUP

- F (Coal)

- G (Grain)

TEMPERATURE CLASS

- T4 (135°C)

CERTIFICATION MARK

- UL

- Certified and listed to applicable UL standards

CAPACITY RANGE

- 1 Ton – 5 Ton

VOLTAGES

- 208-230V-3-60

- 440-460V-3-60

BRAKE

- “The Guardian”: Smart Brake Technology

- Revolutionary DC current motor brake with electrical failsafe design

- 10 year warranty

CONTROL

- Single Speed Contactor

CONTROL VOLTAGE

- AC110V

DUTY CYCLE

- Hoist - 60 Min.

- Trolley - 30 Min.

CLASSIFICATION

- ASME H4

- ISO M5 or M4

- FEM 2m or 1Am

RATINGS

- Hoist – IP55

- Pendant – IP65

UPPER/LOWER LIMIT SWITCH

- Overwinding/overlifting device

- Standard on all models

CORROSION RESISTANT LOAD CHAIN

- Nickel-plated, Grade 80, DIN chain for superb durability and strength

HIGH AIR FLOW

- Cooler motor and brake attributed to an engineered motor fin, fan blade and fan cover design

LONG LIFE FRICTION CLUTCH

- Protects hoist from damage and prevents overwinding

POWER SUPPLY & CONTROL

- Direct wire

REGISTERED TRADEMARK

- The black and yellow trade dress is a registered trademark of Kito, Fed. Reg. No. 7,342,071. All Rights Reserved.

OPTIONS

- Canvas, plastic or steel chain containers

- Hook, lug or trolley configurations